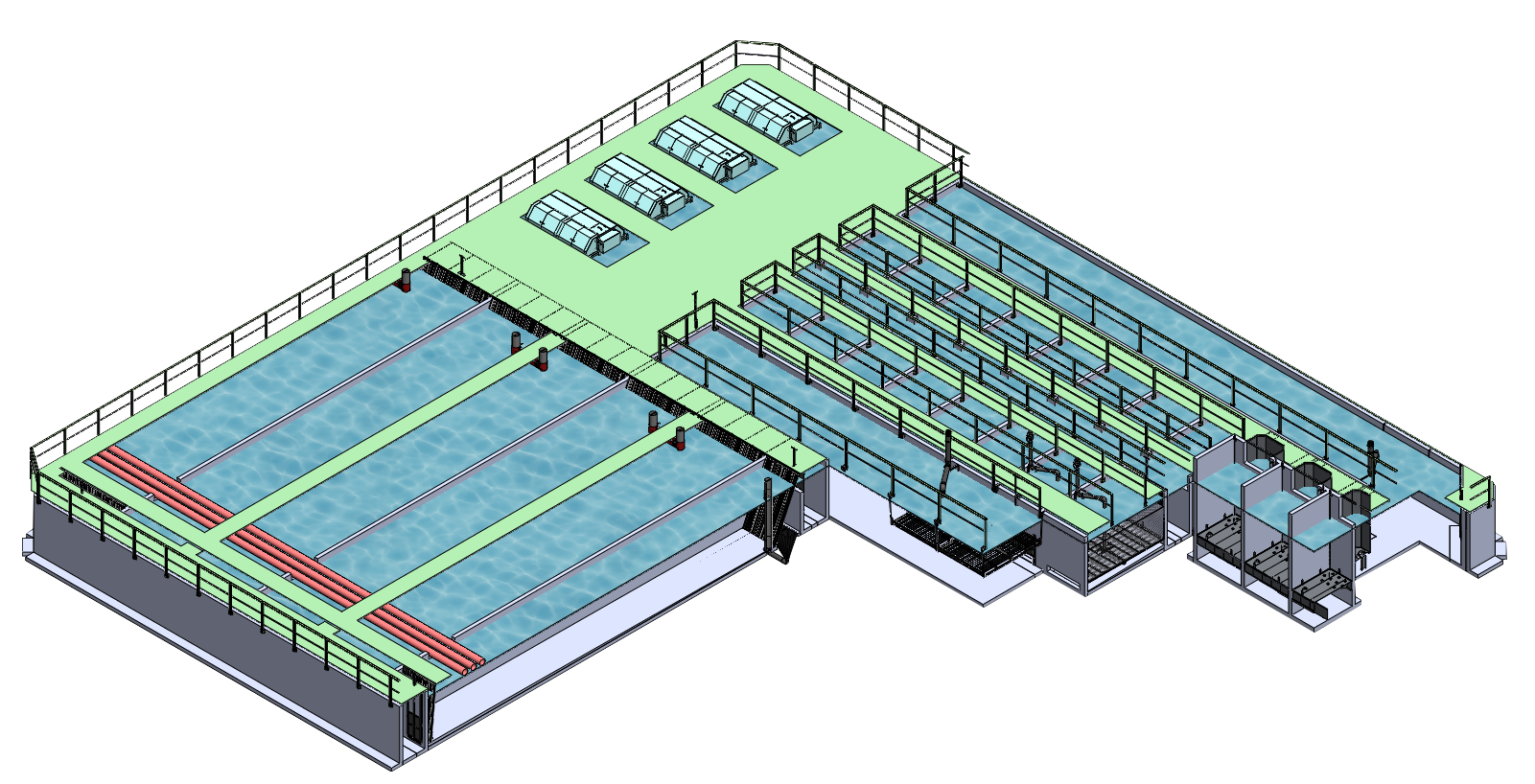

The FREA concept

FREA stands for Fully Recirculated Aquaculture System. This innovative fish farming concept takes recirculation within aquaculture to a new technical and environmental level, as the thinking behind recirculation is implemented 100% in the entire process.

Udfiskningsrør

Micro sieve (option)Tromlefiltre (option)

Inlet channelFødekanal

Fish channelFiskekar

Sludge coneSlamkegle

GridRist

Oulet channelBagkanal

DegassingAfgasning

Fixed bed biofilterFixed bed biofilter

Fixed bed biofilterFixed bed biofilter

Oxygen platformIltplatform

Circulation pumpCirkulerings pumpe

Basic principles in the FREA concept

In a recirculated plant of this type, there is no direct discharge to the water environment. The particular substances are removed and fermented for later use as fertiliser, or fuel in biogas facilities. The surplus water is discharged into large percolation basins, where it percolates for full or partial recycling and reused in production at the plant.

If the plant is established on poor soil with a large sand and gravel content, the natural conditions for water recycling and percolation of the necessary volumes of water would be significantly better than on rich soil with mull and clay.

The water intake is constructed as horizontal drains at a depth of 4-5 metres, depending on the soil, and the positioning will be both underneath the percolation area and on the ground at the side of the percolation area. The percolation area is established as basins with horizontal overflow pipes in the middle for a uniform distribution of the discharge water.

The limited water replacement means the water remains in the plant for approx. 6 days, which can be compared with the legal requirement for 18.5 hours in a type 3 model farm. At the same time, the plant’s functionality and the very high degree of water recycling means the effect of the purification measures is significantly improved.

The water in the fish tanks is purified by being directed over sludge cones, after which the water flows through both fixed and moving bed bio-filters. Micro-sieves have not been installed at FREA A/S.

The plant is divided into separate sections for hatchery, fry, fingerling and portion size fish, and further division is made within the individual section. This reduces significantly the overall risk of extensive outbreak of disease and the spread of infection.

The division also makes it possible to use the “all in - all out” principle in production planning, which is in line with the principles that apply to the breeding of a number of other live animals.

As production is carried out exclusively by using drainage water and ground water, the risk of contamination with environmentally harmful substances from water sourses will be removed.

The FREA plant has a low energy consumption. FREA A/S operates with an energy consumption of around 1.5 KWh/kg of feed.